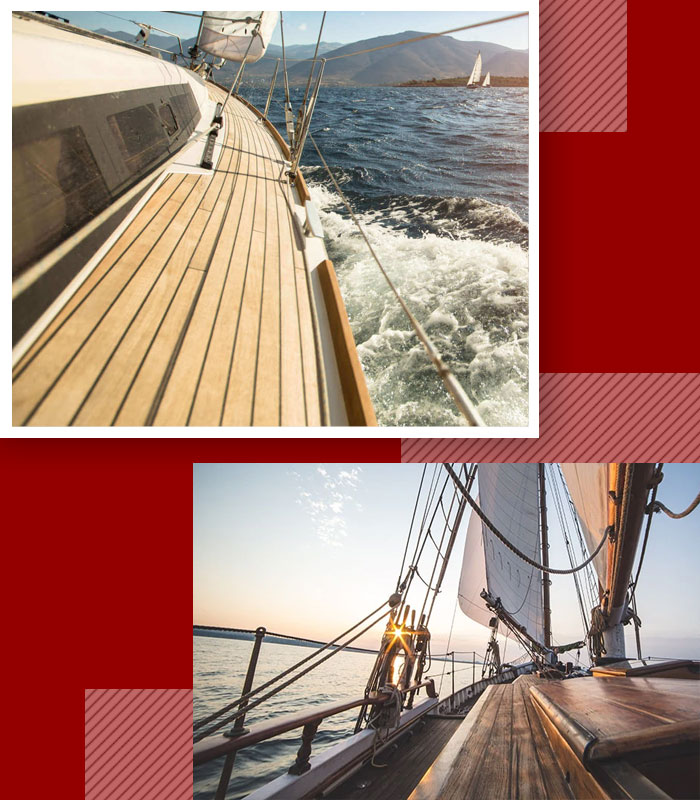

Modak Ply is the leading Marine Plywood Manufacturer and Supplier in India. We are contributing to the plywood industry as a superior supplier of marine plywood in the market. We are working to manufacture the diverse range of marine plywood however marine plywood is our dominance. We produce the Plywood in various orders like we are the authorities of demonstrating striking plans, structures which are commonly used in furniture.

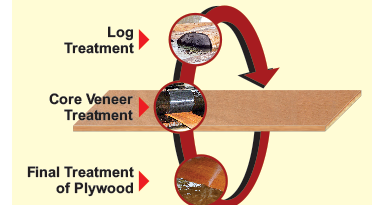

These are made frequently from hardwoods; marine grade plywood is built to be exceptionally water-safe. These woods have a littler center hole, decreasing the dangers of water effects. This marine plywood likewise has a protection from termites and borers.Marine Plywood Manufacturer; In different cases, the facade would be synthetically treated to give water, termite and borer opposition. The holding pitch is exceedingly water-safe, in order to anticipate the facade sheets from delaminating from one another when the plywood interacts with water. This is a standout amongst the most practical and sturdy alternatives with regards to making your home furnishings.

KEY FEATURES:

- Increase Stability

- Flexible

- 100% boiling waterproof

- Water Resistant

Our Marine laminate certified with British Standard 1088, that could be a British customary for marine laminate. Modakply is one of the best quality Marine Plywood Manufacturer, Marine Plywood Manufacturer in India, Marine Plywood Manufacturer in Delhi. Our customers are satisfied with our Marine Plywood, we have Rated 4.2/5 by 1035