Modak Ply is one of the best marine plywood manufacturers known for providing exceptional resistance to moisture, humidity, termites, and borers in our marine plywood. We have gained a widespread reputation for premium products and customer-satisfying services by offering impeccable quality plywood for high-moisture conditions. From product planning to final delivery, everyone associated with Modal Ply dedicated themselves to producing optimum quality marine plywood. With a streamlined flow of sophisticated machinery, we can handle numerous client requirements related to marine plywood, making us one of India's top marine plywood suppliers.

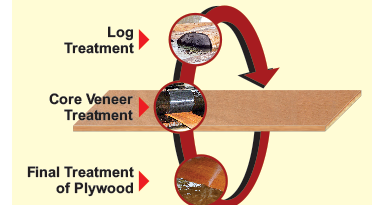

Our marine plywood is specially designed to withstand highly moist conditions where other plywood crumbles and rots quickly. Only high-grade hardwood extracted from trees like mahogany, teak, or birch is used to cut marine plywood veneers. It has multiple layers for added strength and dimensional stability. The thing that gives our marine grade plywood its main advantage, i.e., water resistance, is phenol formaldehyde- a high-water repellant adhesive that we use to bind the layers of veneers together. The water resistance and dimensional stability make it withstand moist conditions much longer than other types of plywood without delaminating, swelling, or warping. Besides being dense and water resistant, it has significantly fewer voids and gaps to prevent water penetration.

KEY FEATURES:

- Increase Stability

- Flexible

- 100% boiling waterproof

- Water Resistant